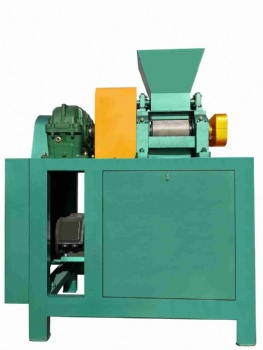

oscillating granulator

Equipment overview

The oscillating granulator develops the wet powder or block-like dry material into the required granules. The wet powder mixture is mainly used for forced passage through the screen under the positive and negative rotation of the rotating drum to make granules. equipment.

This machine is mainly used in the pharmaceutical, chemical, food and other industries to produce various specifications of particles, which are dried into various shaped products. The machine can also be used to crush dry materials that are condensed into blocks. All materials contacting parts are made of stainless steel. Material production.

structure

1. Main body: The machine body is an independent rectangular cylinder, on which a closed bearing seat is connected to the powder hopper, and the powder hopper extends toward the body.

2. Pellet manufacturing device: The rotating drum is placed horizontally under the powder hopper, and there are bearing supports at the front and back. It is driven by the rack to rotate backwards and forwards. The front bearing cover on the end face is movable. The next wing nut, the bearing cap and the rotating drum can be drawn out, and the two ends of the drum are placed with convex square rings.

3. Gearbox: It adopts worm gear transmission, the oil can be stored in the box, and there is a sight glass on the box to observe the operation and oil storage. The outer end of the worm gear is equipped with an eccentric shaft to drive the rack to reciprocate.

4. Screen clamp pipe: The device is installed on both sides of the rotating drum, made of steel pipe, with a long groove in the middle, and the two ends of the screen are embedded in the groove, and the flower-shaped handwheel is turned to wrap the screen on the outer circle of the rotating drum. The hand wheel is supported by gears, and the tightness can be adjusted.

5. Motor frame: one bolt is fastened to the screw, and the motor is installed on the iron plate. When the screw bolt is turned, the motor moves up and down to adjust the belt.

Features

1. The whole machine has the advantages of compact structure, beautiful appearance, convenient cleaning, simple operation, high output and low energy consumption.

2. The contact parts of the materials are made of high-quality stainless steel and polished, with good finish, easy to clean, low noise, no wear, easy to operate and maintain, and meet GMP requirements

Model | Capacity(kg/h) | Power(kw) | Roller speed(r/min) | Swing agle(0) | Roller (mm) | Size (cm) | Weight(kg) |

YK-60 | 20-30 | 0.25 | 46 | 360 | 60 | 45x45x55 | 70 |

YK-90 | 30-200 | 1.1 | 55 | 360 | 100 | 70x40x105 | 180 |

YK-160 | 60-300 | 2.2 | 55 | 360 | 160 | 100x80x130 | 280 |

YK250 | 150-400 | 4.5 | 55 | 360 | 250 | 130x100x150 | 400 |

YK320 | 200-600 | 7.5 | 55 | 360 | 320 | 150x130x165 | 600 |

售前客服

售前客服