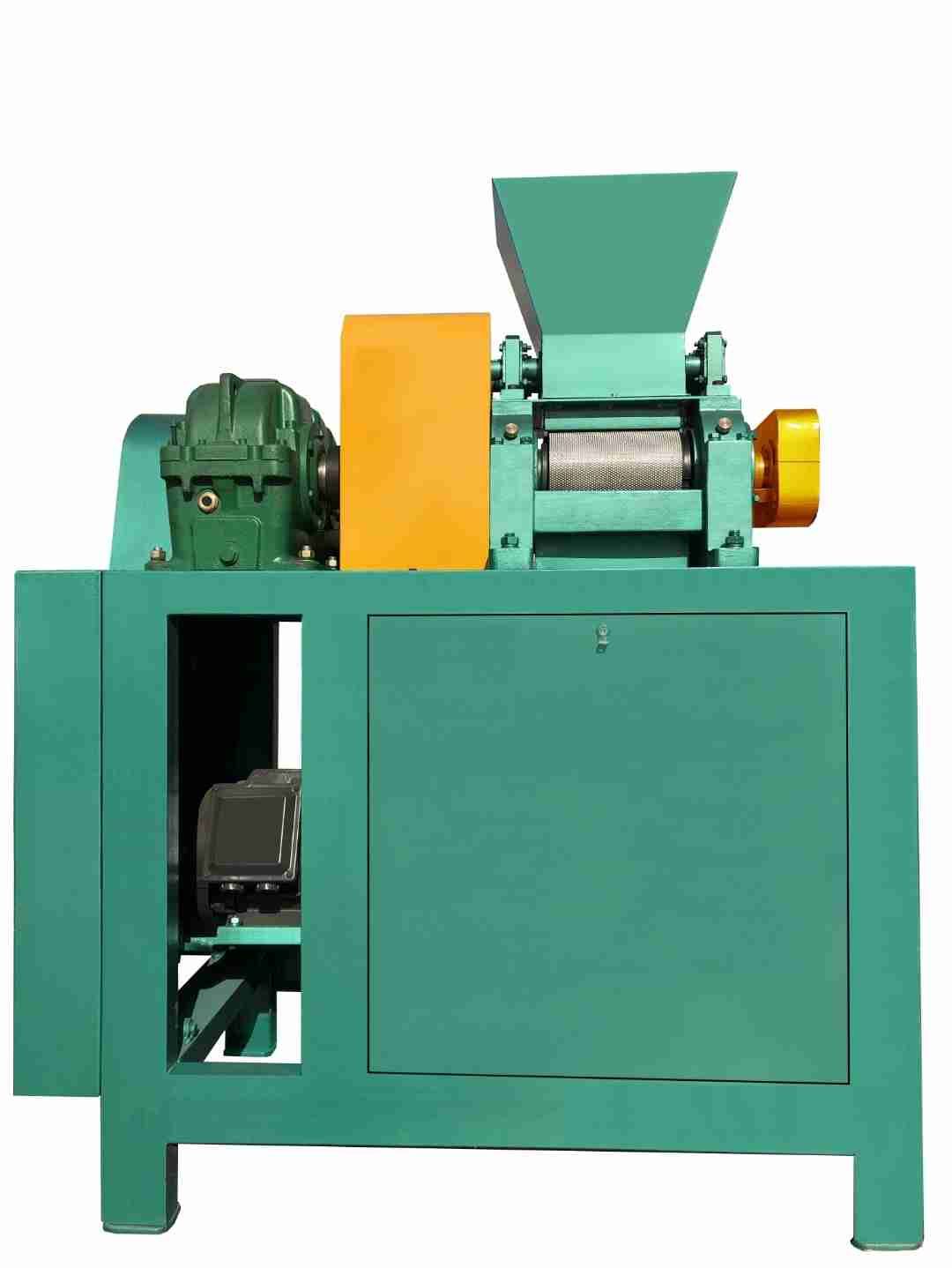

Roller extrusion granulator

A roller extrusion granulator is a machine used for granulation.

It features wide material adaptability, suitable for many raw materials like fertilizers, medicines, etc. It has a high granulation rate (usually over 85%). It's energy - saving and environmentally friendly as it granulates at room temperature without drying steps and has no waste discharge. It also has low investment and high efficiency.

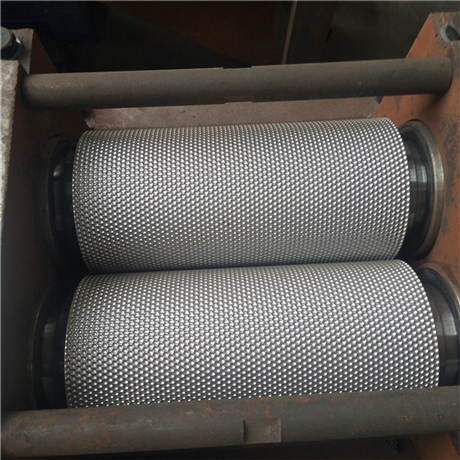

The working principle involves extrusion, where dry material enters the hopper and is compressed into a mass between two rotating pressure rollers. Then, the extruded mass is cut into particles. The size and shape of particles can be controlled by adjusting the gap and speed of the rollers.

A roller extrusion granulator is a key equipment for granulation, which has the following features and working principles:

Features

Working Principle

Overall, the roller extrusion granulator is widely used in many industries due to its advantages of high efficiency, energy saving, and strong adaptability.

| Model | Granule Diameter (mm) | Roll Skin Size (mm) | Feed Moisture | Granule Output (t/h) | Power (kW) | Overall Dimensions (mm) |

|---|---|---|---|---|---|---|

| JZ-1T | 3 - 10 | Φ150×220 | ≤10% | 0.8 - 1.2 | 11 when the granule ≤ 4.5mm; 15 when the granule ≥ 4.5mm | 1450×800×1450 |

| JZ-1.5T | 3 - 10 | Φ150×300 | ≤10% | 1.2 - 1.8 | 18.5 when the granule ≤ 4.5mm; 22 when the granule ≥ 4.5mm | 1450×850×1500 |

| JZ-2T | 3 - 10 | Φ185×300 | ≤10% | 1.5 - 2.5 | 22 when the granule ≤ 4.5mm; 30 when the granule ≥ 4.5mm | 1630×850×1650 |

| JZ-3T | 3 - 10 | Φ300×300 | ≤10% | 2.5 - 3.5 | 37 when the granule ≤ 4.5mm; 45 when the granule ≥ 4.5mm | 1850×1100×2050 |

售前客服

售前客服