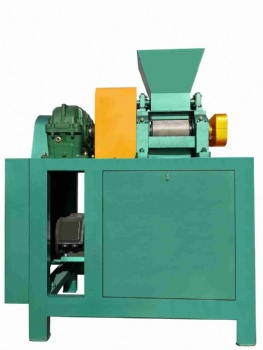

screw extruder

A screw extrusion granulator is an important device for converting powder materials into granules. It functions by feeding the material into the machine, where the rotating screw pushes and compresses it in the extrusion cavity. The material then passes through the die to form granules of the desired shape and size.

This equipment is commonly used in chemical, pharmaceutical, food, and other industries. It can handle various materials and has the advantages of being able to control the granule parameters and being cost-effective. For example, in the chemical industry, it helps produce uniform and high-quality fertilizer granules. In general, the screw extrusion granulator is highly efficient and plays a significant role in improving production processes and product quality.

Product Description

Applied Scope:

The extruder is widely applied to material needs granulating such as rubber auxiliar,foodadditive, plastic auxiliary,catalyzer, agrochemicals, dye, pigment, daily chemicals,medicine etc.

Working principle:

SE series of screw type extruding pelleterinclude single-screw type and double-screw-type.Two models of front and side for material to be extruded out.Wet material or materialwith low melting point(general means<50ºC)after being kneaded and mixed shall be extrudedout from mould plate at the head of the plant due to being conveved and pressed by screws.and then be dried or cooled to form end products of particles so as to complete the courseof chanaina material from powder to particle,The shape of arain is cvlindrical.The diameterof end grain can be chosen and controlled by means of changing the diameter of holes in themould plate: for side type is 0.7-2.0mm.for front type is 1.5-1.2mm.The rate of end productis equal to or more than 95%.

Main Features:

As the powder material is kept in wet state during the whole process of granulation.he workina conditionis areaty promoted Flying of dust is generally reduced to over 90% of that used to be. Some phenomenon that well influent application such as curdling, framing, pulsing etc can be averted by means of granulationAs the stacking specific gravity can be increased generally, space for transporting, storing, packing can be effectively saved. As for products composed of muti-component or mixed distributed, the segregation of each component can be avoided though granulation so as to guarantee the quality of compound products.

New design, adding internal propulsion blades at the end of the screw, can better increase pressure and prevent clogging.

Add a scraper at the outlet according to user requirements to obtain more uniform length particles.

The hopper stirring device prevents raw material clogging.

The cooling water circulation jacket design reduces the heat generated by extrusion.

| Main Technical Parameters | |||||

| SET Double-screw extruder | SES Single-screw extruder | ||||

Model | Screw diameter (mm) | Power (kw) | Model | Screw diameter (m m) | Power (kw) |

| SET-60 | 60 | 5.5 | SES-80 | 80 | 7.5 |

| SET-100 | 100 | 7.5 | SES-120 | 120 | 15 |

| SET-140 | 140 | 15 | SES-160 | 160 | 22 |

| SET-180 | 180 | 30 | SES-200 | 200 | 37 |

售前客服

售前客服