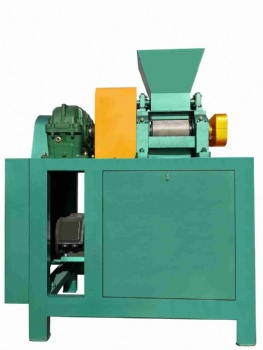

rotary extrude granulator

The part in contact with the material of the rotary granulator is made of stainless steel, with beautiful appearance, reasonable structure, high granulation forming rate, beautiful granules, automatic discharging, avoiding particle damage caused by manual discharging, and suitable for flow operation.

Scope of use

1. The granulator is a kind of swinging action with a rotating drum. The wet powder material can be ground into granules through an iron wire screen, and it can also be widely used to crush the lumps into ready-made granules. 2. In the aspect of chemicals, the powder used as a wettable powder is ground into granules. After drying, it is used to compress tablets. It can also be crushed during storage and agglomerated into agglomerates or agglomerated in the process of chemical processing. In industry, it is used to process candy and sugar mixture and malt milk and other products. In other industries, such as ceramics, plastics and other mixtures become shaped particles. 3. It is not suitable for semi-solid, fluid, slurry or abrasive use.

principle

Make the two ends consistent with the line speed of the inner and outer ring of the mold, and there is no dislocation friction between the wheel and the mold, which reduces the resistance, reduces the kinetic energy loss, and prolongs the service life of the mold. This is a major difference from similar compression molding equipment. . It adopts the screw center pressure regulating mechanism, and the mold gap is as large as the small, suitable for different materials, ensuring the pressing effect. Its pressure roller adopts a large groove width, bearing pressure and wear resistance, and a plurality of pressure rollers are uniformly distributed, and the operation is stable. At the same time, the pressing area is increased, and the production efficiency is improved. Compression molding of wood chips and straw requires a lot of pressure. In similar pelletizing, briquetting, and rod making equipment, the pressure wheel is the central part of the entire equipment. The advantage of the "cone wheel flat die" that the pressing wheel can be enlarged arbitrarily is incomparable to other equipment. For example, the ring model granulator is limited by the diameter of the ring die, and the pressing wheel cannot be enlarged, resulting in the change of the pressing wheel bearing chamber. Small, the assembled bearing does not have strong pressure-bearing ability, and the damage of the bearing causes the disadvantage of three stops and two rests of the equipment. The compression molding of this model is diversified, and round bars, squares, and pellets can be made as long as the mold is changed. It is suitable for compression molding of different materials and achieves the best benefits. The granulation room is equipped with an observation door for easy maintenance and repair at any time.

ZL series rotary granulator

This machine is used in the pharmaceutical, food, granular, chemical, solid beverage and other industries to make the mixed materials into the required particles, especially suitable for materials with higher viscosity.

Features:

All parts in contact with the material are made of stainless steel, with beautiful appearance, reasonable structure, high granulation forming rate, beautiful granules, automatic discharging, avoiding the damage of granules caused by manual discharging, and suitable for flow operation.

Application field

XL series rotary granulator is used in pharmaceutical, food, granules, chemical, solid beverage and other industries

This equipment has been innovatively designed to add a scraper to ensure uniform and beautiful particles and prevent particles from being too long.

型号 type | 250 | 300 |

粒子直径diameterof granule (mm) | φ2-2.2(可根据用户需要 It may be in accordance with the requirements of customers) | φ1.2-3(可根据用户需要 It may be in accordance with the requirements of customers) |

外形尺寸 Overall dimesions (mm) | 700×540×1300 | 880×640×1300 |

电机功率 power of motor (kw) | 3 | 4 |

重量 Weight (kg) | 350 | 400 |

生产能力 Production capacity (kg/h) | 100-200 | 140-400 |

售前客服

售前客服